Diesel Electric Plant

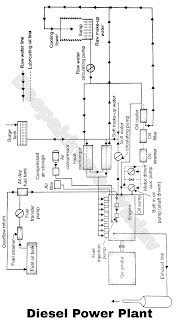

Main Components : The essential components of a diesel electric power plant are as follows :

- Engine.

- Engine fuel system.

- Engine air intake system.

- Engine exhaust system.

- Engine cooling system.

- Engine lubrication system.

- Engine starting system.

- A.C. or D.C. generator.

- Engine : It is the main component used in the plant for developing mechanical power to run the generator, it is coupled directly to the generator to produce electric power.

- Engine fuel system : It consists of fuel storage tank, fuel transfer pump, strainers, heaters and connecting pipe work. Fuel transfer pumps are needed to transfer fuel from delivery point to storage tank and from storage tank to engine. Strainers clean the fuel. Use of heater is required especially during winter to heat the oil.

- Engine air Intake system : This system includes air filters, ducts and super-charger. Air filters remove dust from the air to be supplied to the engine for combustion. The super charger increases the pressure of the air supplied to the engine, for increasing the power output. They are generally driven by the engines.

- Engine exhaust system : This consists of silencers and connecting ducts. As the temperature of exhaust gases is sufficiently high, it is used for heating fuel oil or air supplied to the engine while the silencer reduces the noise level of the engine.

- Engine cooling system : The engine cooling system consists of coolant pumps water cooling towers or spray ponds, water treatment or filtration plant and the connecting pipe work. The cooling system is required to carry heat from engine cylinder to keep its temperature within safe limits. The pump. circulates water through cylinder and head jackets to carry away the heat. Hence, the cooling system consists of a water source, a pump and a pond. When the same water is to be reused then for cooling it, devices like radiator, evaporative coolers, cooling tower spray ponds etc. are required.

- Engine lubrication system : Engine lubrication system consists of lubricating oil pumps, oil tanks, filters, coolers, purifiers and connecting pipe work. This system provides lubricating oil to the moving parts of the system to reduce the friction between them reducing wear and tear of the engine parts.

- Engine starting system : The function of the starting system is to start the engine from stand still or cold condition by supplying compressed air. This system includes storage battery, compressed air tank, self starter etc. The system enables the engine to rotate Initially while starting, until the firing starts, and the engine runs on its own power.

- A.C. or D.C. generators : Generally , three phase, 50 Hz generators are coupled with the shaft of the engine. The voltage developed depends upon system voltage and may be 3.3 kV, 6.6 kV or 11 kV. The A.C. generators are salient-pole type, the number of poles depends upon the speed of the engine. Generally, speed of the engines are low, hence, 6 pole or 8 pole construction can be used. In the pole faces, damper windings are provided to obtain a stable operation of generator.

- In case of small and isolated units, single phase 230 V, 50 Hz generators can be used as per the requirement of isolated loads.

- When D.C. generators are coupled they are mostly level compounded compound generators, developing 230 volts.